40 Years Servicing The Printing Industry

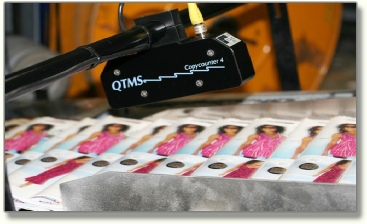

Commercial product count

Commercial print product, from an optical perspective creates the most difficult challenge for the count sensor designer.

From job to job:

- Paper thickness varies widely

- Paper coating reflectivity varies

- Paper absorption varies

- Delivery speeds vary

- Edge folds can vary

- Page count varies

The CC 4 is design with the ability to manage the variations without having to adjust settings, saving time and effort on the part of the operators.

Gripper count

The Copycounter, mounted after a drop gate

(waste gate) will provide an accurate count

of the copies jettisoned from the production run.

No moving parts and non-contact makes this

sensor ideal for replacing mechanical “finger”

counters.

This sensor does not use lasers and so has no

health and safety issues to consider for people

passing under the unit looking into the beam.

Ideal sensor for any business with shop floor

data collection.

Gripper count

The Copycounter, mounted after a drop gate (waste gate) will provide an accurate count of the copies jettisoned from the production run.

No moving parts and non-contact makes this sensor ideal for replacing mechanical “finger” counters.

This sensor does not use lasers and so has no health and safety issues to consider for people passing under the unit looking into the beam.

Ideal sensor for any business with shop floor data collection.

Newspaper product count

Newspaper is a difficult product to count. The paper is absorbent and wrinkles as it dries and often creases in the folder. The analyser circuitry reduces the effects of wrinkles and creases and enhances the leading edge detection, making it the obvious choice for newspaper counting.

The Copycounter is a winner for:

- Thin copy counting

- Thick copy counting

- Inserted product counting

- Accurate stacker batching

Accurate edge detection for compensating stackers

Leading edge detection

“Leading edge detection” is the ability of the sensor

to detect the leading edge of the product and transmit the information with no processing delay so that equipment operating downstream knows exactly where, on the conveyance, the product starts.

This is vitally important for:

- Labelling machines

- Compensating stackers

- Batching stackers

- Gripper pick-up stations

- Winding stations

Copycounter 4 is the ideal solution.

For stacker count

The ideal counting sensor for all stackers:

- Easy to install

- No maintenance

- Very long life > 8 yrs

- No “teaching” (setting up each job)

- Allows accurate batching

The Copycounter has been installed and run successfully on almost every type of stacker made over the last 25 years.

Its accuracy makes it the sensor of choice for any business that uses the stacker count as input to its shop floor data collection systems.

Tech Spec:

Dimensions: 181 x 68 x 39.2 mm

Weight: 515 gms (1.1 lbs)

Count rate: 360,000 products/hour

Product range: 0.2mm (single sheet white) upwards.

Op range: 85mm (+/- 45 mm)

Power: 24VDC (+/- 6VDC) at 0.125 Amps

Fuse: Auto-reset (on power and signal track)

Output: NPN (sink) isolated (max: 100mA, 50V)

Connection: M12 4 way female

Signal settings: 5, 12 and 20-100 (adjustable) msec.

Warranty: All parts and labour 3 years

It arrives in a carton with:

- Mounting block for 3/4” (19mm) bar

- Cable, 5 metres screened

- Installation manual

For conveyor delivered count

This is the most obvious application of the Copycounter.

Its real-time analyser and high quality optics separate the leading edge from ripples in the product surface with ease.

Uniquely we can say:

- Badly spaced product

- not a problem

- Rotated or displaced product

- not a problem

- Counting copies after a waste gate where the copies can arrive displaced or bunched

- not a problem

© 1982 - 2020 MCM EUROPA BV all rights reserved.

voor Nederlands klik hier